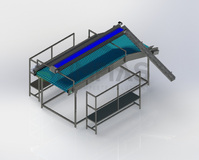

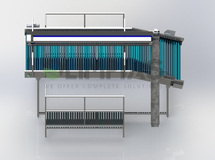

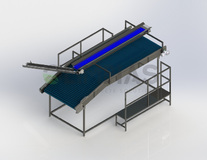

Elevator-Inspection table

The elevator – inspection table, is a specially designed machine consisting of rollers, used for fruit processing. It is meant to be a part of a more complex processing line for packaging and/or sorting products. The machine starts running and operates through switches on the electric board. Part movements are automated.

The machine consists of the following:

- Incline roller elevator.

- Inspection table.

Machine general breakdown:

- The external parts of the machine are constructed from painted structural steel framework and plates, welded and/or bolted.

- The internal parts that come in contact with the product are made of stainless steel.

- The machine’s stands are height adjustable.

- The loading hopper is lined with an elastic material in order to protect the processed products from bruising.

- The diameter of the rollers is Φ48 and the material used is subject to product requirements. Usually used materials are: PVC, Metal, Aluminium Alloy and INOX.

Product transporting speed can be adjusted mechanically or electrically through an Inverter.

The normal work cycle is as follows:

- The operator feeds the loading hopper with products.

- The products roll onto the incline roller elevator and inspection table, where the moving – rotating line of rollers rotates them in such a way, to facilitate the operator in the sorting process.

- Staff performs manual visual control and inspection of the products on the inspection table.

- The products are then transported to the end of the roller section for further processing.